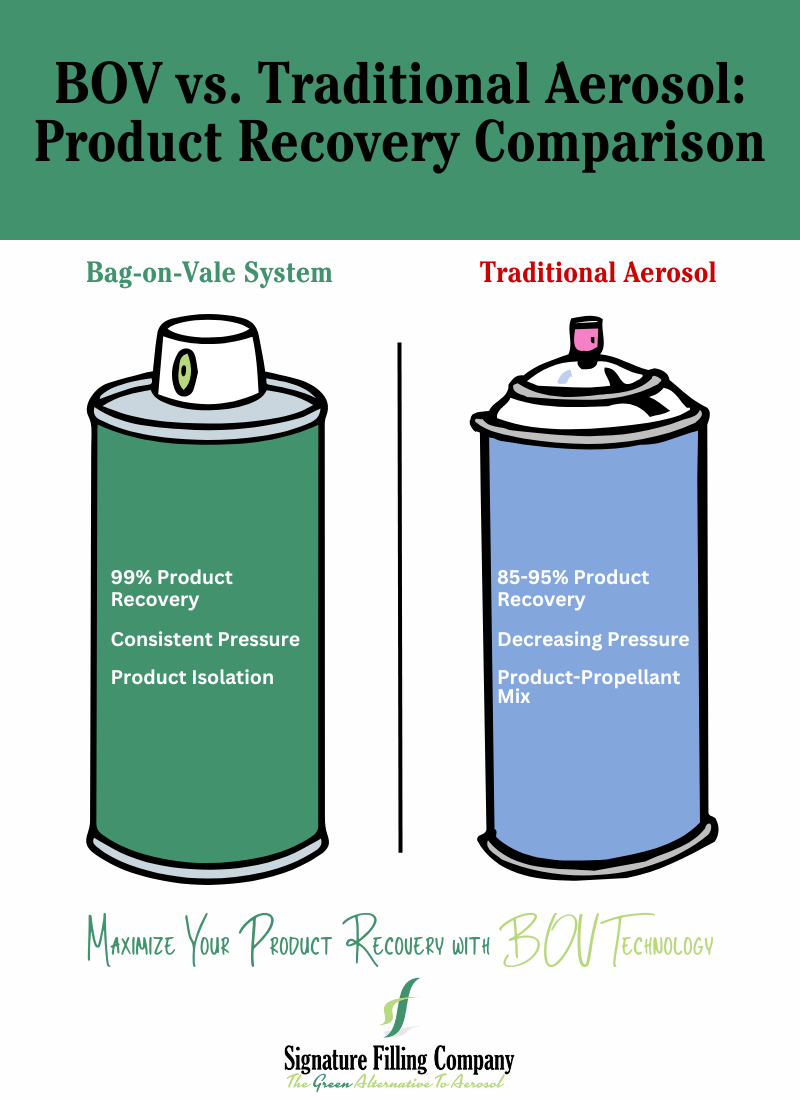

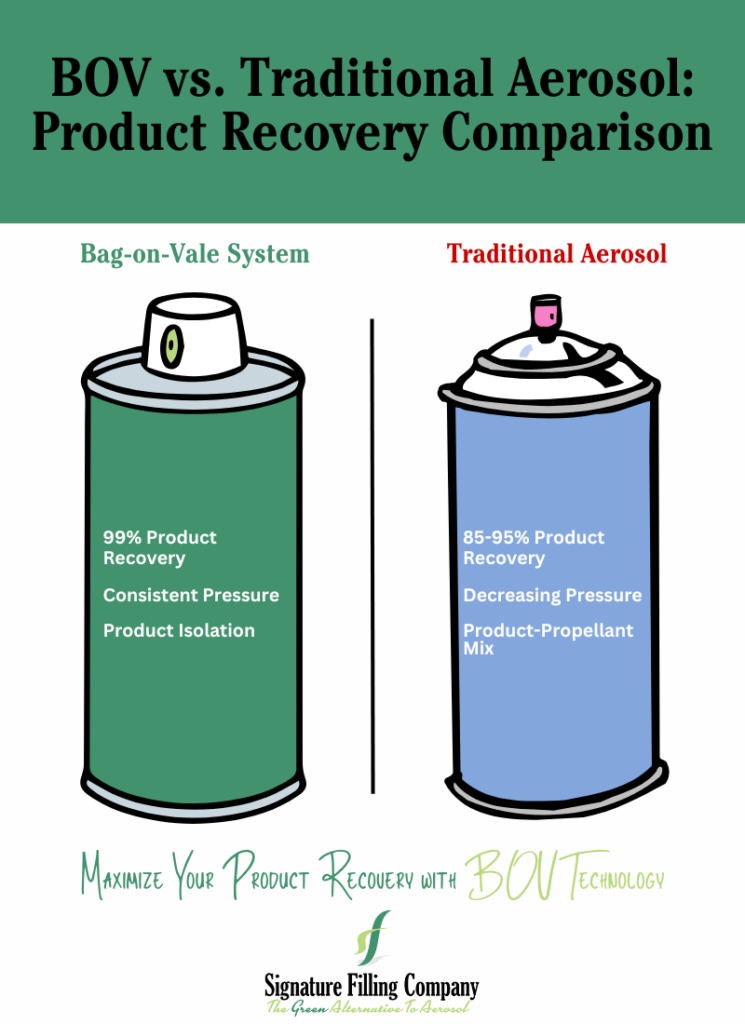

Maximizing Product Recovery: BOV’s 99% Emptying Technology Explained

In today’s competitive manufacturing landscape, product waste isn’t just an environmental concern—it’s a significant cost factor that directly impacts your bottom line. Bag-on-Valve (BOV) aerosol technology has revolutionized product delivery systems, offering an unprecedented 99% product recovery rate. For manufacturers and brands seeking superior aerosol packaging solutions, understanding how BOV technology achieves this remarkable efficiency is crucial for making informed packaging decisions.

The Hidden Costs of Traditional Aerosol Systems

Traditional aerosol packaging systems typically leave 5-15% of product unused in the container. This waste translates to significant losses:

- Increased cost per unit due to unused product

- Higher disposal and environmental impact costs

- Reduced customer satisfaction from incomplete product usage

- Additional manufacturing runs to compensate for waste

The BOV Advantage: Understanding 99% Product Recovery

Signature Filling Company’s Bag-on-Valve technology achieves superior product recovery through a sophisticated yet elegant design. The system consists of several key components working in harmony:

1. The Advanced Bag System

Our BOV systems utilize FDA-approved laminated aluminum bags with 3-4 layers, depending on specific product requirements. This specialized construction ensures:

- Complete product isolation from the propellant

- Superior protection against oxygen degradation

- Optimal flexibility for maximum emptying

2. Precision Valve Technology

Available in both female and male configurations, our BOV valves are engineered for optimal flow and complete product evacuation. The valve system:

- Maintains consistent product flow from first to last spray

- Enables precise dispensing control

- Prevents product contamination throughout use

3. Propellant Innovation

Unlike traditional aerosols, BOV systems separate the product from the propellant, using compressed air or nitrogen. This separation delivers multiple benefits:

- Consistent spray pressure until the last drop

- Environmentally friendly propellant options

- Enhanced product stability and shelf life

Real-World Applications and Benefits

Personal Care Products

For premium cosmetics, pharmaceuticals, and skincare products, BOV technology ensures:

- Complete delivery of expensive formulations

- Preservation of sensitive ingredients

- Enhanced user experience with consistent application

Food Grade Applications

In food applications such as cooking oils and sprays, BOV systems provide:

- Maximum recovery of premium ingredients

- Consistent spray patterns throughout use

- Superior product freshness

Industrial Solutions

For industrial products like lubricants and technical sprays, benefits include:

- Precise application without waste

- Consistent product delivery at any angle

- Reduced environmental impact

Cost Savings Analysis

Implementing BOV technology delivers measurable returns:

- Direct Product Savings

- Up to 15% more product recovered compared to traditional systems

- Reduced waste disposal costs

- Lower environmental impact fees

- Production Efficiency

- Fewer production runs needed for same output

- Reduced cleaning and maintenance requirements

- Improved production line efficiency

- Market Advantages

- Premium positioning opportunities

- Enhanced sustainability credentials

- Improved customer satisfaction

Manufacturing Excellence Through Lean Principles

At Signature Filling Company, we maximize customer value while minimizing waste through lean manufacturing practices. Our BOV filling processes ensure:

- Consistent quality control

- Efficient production scheduling

- Flexible run sizes to meet varying demands

- Complete technical support throughout the process

Implementation and Quality Assurance

Our comprehensive approach to BOV technology implementation includes:

- Complete technical support

- Custom formulation services when needed

- Flexible manufacturing capabilities

- Rigorous quality control processes

- Full regulatory compliance support

Making the Switch to BOV

Transitioning to BOV technology is a strategic decision that requires careful consideration of:

- Current product specifications

- Production volume requirements

- Target market expectations

- Sustainability goals

- Cost optimization objectives

Take the Next Step

Ready to explore how BOV technology can revolutionize your product delivery and boost your bottom line? Contact Signature Filling Company today to discuss your specific needs. Our team of experts can help you:

- Evaluate your current packaging efficiency

- Calculate potential cost savings

- Develop a custom implementation plan

- Create product samples for testing

Don’t let valuable product go to waste. Discover how our BOV technology can deliver 99% product recovery for your aerosol packaging needs.